Want to learn more?

Scroll down for more information

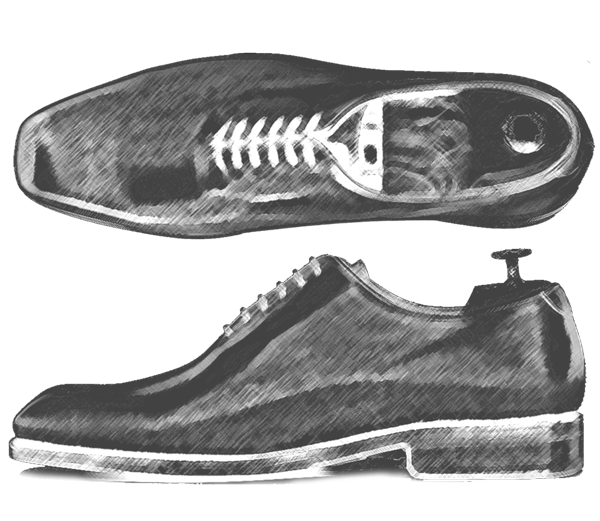

The Whole Cut, a brief description

Often considered the most formal men's shoe available, the Wholecut features closed channel lacing and is made from a single cut of leather. The sleek design and limited stitching make for an elegant and highly sought-after style.

Original Goodyear Welted

Original Goodyear Welted shoes have always been associated with excellence and superior workmanship. This construction process is expensive, time consuming and requires highly skilled craftsmanship. For instance, more than 60 craftsmen are involved in the process of manufacturing one of our Goodyear shoes, requiring more than 120 production steps, from beginning to end.

Invented hundreds of years ago, Goodyear is still considered one of the finest method of shoe construction today. The construction get its strength, durability and repair qualities by stitching the upper leather, lining leather and welt (a specially prepared piece of leather) to the ribbing that has already been bonded to the insole. The welt is then stitched to the leather or rubber sole. It is this final stitch, holding the sole in place, which we can cut through enabling complete removal of the sole without causing damaging the upper.

Full Calf Lined Interior

These shoes are fully-lined with soft calfskin leather, which means ultimate comfort. Most companies will only partially line their shoes, but we go the extra mile because it means a more comfortable shoe and less break-in time.

What is MTO Standard Production?

Made-to-Order shoes are entirely produced on demand, strictly following your design instructions. After a purchase is made, the shoes begin their production journey. From material hand cutting, to the sole being stitched to the upper. Every part of the shoe is individually produced and assembled just for your order. It takes our artisans between 3 and 6 weeks to produce a pair of Made-to-Order shoes. Please, remember this when placing your order.

Made with High Grade Box Calf

Box calf is the most traditional leather there is. The grand majority of quality-mens-shoes are made from this kind of material. Box calf is a type of leather taken from calves, and although it has a pliable feel, it is firm in consistency. Box calf leathers are given their final colour and shine at the tannery, which will improve with time and develop a lovely patina.

Hand Painted Crust Leather

Crust calf is untreated –not dyed– leather. It's usually used in its plain form, but it can be embossed with textures like pebble grain, full grain or croco. This leather is hand painted by our maestro colorist using natural dyes and oils.

Being an artisanal process, it is difficult to achieve uniform shades, especially in the lighter ones, although its main attraction is precisely its natural finish and the light transparency in its colors, which gives great distinction and versatility.

The Savile Shoe Last

Used on some of our most refined hand finished shoes, the Savile shoe last is the result of many rounds of refinement to create the perfect men's formal last. Featuring a soft chisel toe and a long elegant vamp, this is a great go-to last for a classic suit shoe.

Additional information

| Finishing | Standard Finishing |

|---|---|

| Shoe Last | Savile Goodyear |

| Materials | Box Calf Leather, Painted Calf Leather |

| Colors | Burgundy, Green |

| Sole | Goodyear Welt, leather sole with mountain rubber injections |

| Service Time | 3-6 weeks |

| Shipping Weight | 2.5 Kg |

| Production Type | Made-to-Order Shoes |

| Lining Type | Full Leather Lining |

| Interior Lining | Beige Calf Leather |

| Construction | Original Goodyear Welted |